Sulfite di sodiu

Tipu di cummerciale: Fabbricante / Fabbrica è Cumpagnia di cummerciale

Pruduttu Principale: Clorur di Magnesiu, Clorur di Calciu, Clorur di Bariu,

Sodium Metabisulphite, Sodium Bicarbonate

Numero di Impiegati: 150

Anno di fondazione: 2006

Certificazione di u Sistema di Gestione: ISO 9001

Situazione: Shandong, Cina (continentale)

Apparizione è apparenza: biancu, cristallu monoclinu o pulveru.

CAS: 7757-83-7

Puntu di fusione (℃): 150 (decomposizione di perdita d'acqua)

Densità relativa (acqua = 1) : 2,63

Formula molécula: Na2SO3

Pesu Molecular: 126.04 (252.04)

Solubilità: Solubile in acqua (67,8 g / 100 mL (sette acqua, 18 ° C), insolubile in etanolu, etc.

Sodium Sulfite hè facilmente intemperatu è oxidatu à sulfate di sodiu in air.Loss di l'acqua cristallina à 150 ℃.Dopu u calore, si fonde in una mistura di sulfuru di sodiu è sulfate di sodiu. A densità di materia anidra hè 2.633. Si ossida assai più lentamente di l'aria secca è ùn hà micca generazioni di decomposizione di sodiu in l'aria secca. sulfite è sulfate di sodiu, è a decomposizione di u cuntattu forte à l'acidu in i sali currispundenti è liberanu l'anidride sulfurosa. U sulfite di sodiu hà una forte reducibilità, è pò riduce ioni di ramu à ioni cuprous (sulfite pò formate cumplessi cù ioni cuprous è stabilizà), è pò ancu riduce l'ossidanti debuli cum'è l'acidu fosfotungsticu. (aghjunghje una piccula quantità d'acqua, agite a reazzione cù u caldu ligeru è dividite u liquidu, a capa di l'etere hè secca cù calce veloce, per qualchi reazzione cù esigenze bassu). Pò esse neutralizatu cù sulfuru di l'idrogenu.

Parte di l'equazioni di reazione:

1. A generazione :

SO2+2NaOH===Na2SO3+H2O

H2SO3 + Na2CO3 = = = scrivi Na2SO3 + CO2 + H2O

2 nahso3 = = delta = = Na2SO3 + H2O + SO2 scrive

2. Riducibilità :

3 na2so3 hno3 + 2 + 2 = = = = 3 na2so4 senza scrive + H2O

2Na2SO3+O2====2Na2SO4

3. U riscaldamentu:

4 na2so3 = = delta = = Na2S + 3 na2so4

4. Ossidazione:

Na2SO3 + 3 h2s = = = = 3 s restante + Na2S + 3 h2o [1]

Preparazione di u laboratoriu

A suluzione di carbonate di sodiu hè riscaldata à 40 ℃ è saturata di diossidu di sulfuru, dopu aghjunghje a stessa quantità di suluzione di carbonate di sodiu, è a suluzione hè cristallizata sottu a cundizione di evità u cuntattu cù l'aria.

Specificazioni

| ITEM | SPECIFICATION | SPECIFICATION |

| Cuntenutu di NA2SO3: | 98% MIN | 96 % MIN |

| NA2SO4: | 2,0% MAX | 2,5% MAX |

| FER (FE) : | 0,002% MAX | 0,005% MAX |

| METALLI PESANTI (AS PB): | 0,001% MAX | 0,001% MAX |

| INSOLUBLE IN ACQUA: | 0,02% MAX | 0,05% MAX |

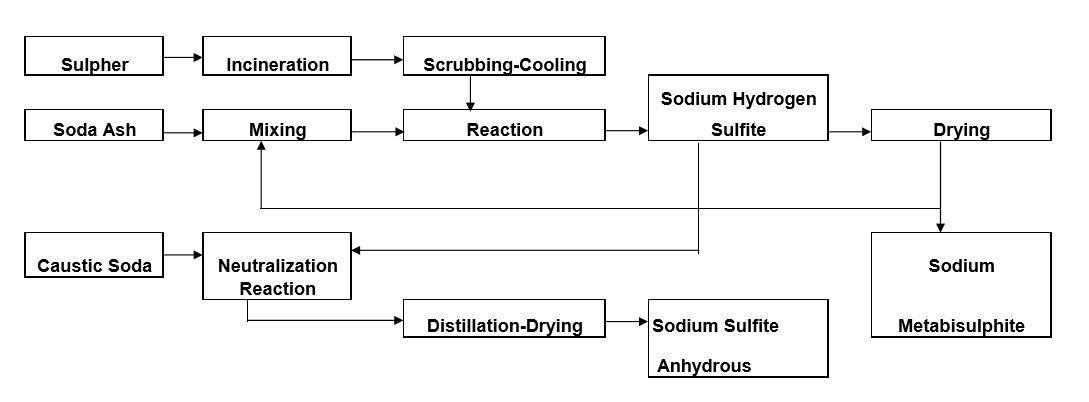

1. Dopu à a fusione, a clarificazione è a filtrazione d'alta efficienza, u sulphur hè aghjuntu à u furnace di sulphur da a pompa di sulphur.

2. Dopu chì l'aria hè cumpressa, secca è purificata, u furnace di sulfuru hè brusgiatu è incineratu sulphur per generà gas SO2 (gas di furnace).

3. U gasu di u furnace hè rinfriscatu da a pignatta di i rifiuti per ricuperà a vapuri, è poi entra in u reattore di desulfurizazione. U sulphur di sublimazione in u gasu hè sguassatu, è u gasu puro cun 20,5% di cuntenutu SO2 (volume) hè ottenutu, è poi entra in a torre di absorption.

4, soda cù una certa cuncintrazzioni di lye, è reazzione di gas di diossidu sulfuru pè ottene suluzione bisulfite sodium.

5, sulfite di sodium sulfite idrogenu suluzione di sodium da neutralizazione di soda caustic pè ottene suluzione sulfite di sodium.

6, suluzione di sulfite di sodiu in u cuncentratore, utilizendu un prucessu di cuncentrazione cuntinuu di doppia effettu.

7. Mettite u materiale qualificatu cuncentratore in a centrifuga per realizà a separazione solida-liquida. U solidu (sulfite di sodiu umitu) entra in u secadoru di u flussu d'aria, è u pruduttu finitu hè seccu da l'aria calda.

U licore madre hè riciclatu à u cisterna di distribuzione alkali per u riciclamentu.

1) Adupratu per l'analisi di traccia è a determinazione di u telluriu è u niobiu è a preparazione di suluzione di sviluppatore, ancu utilizatu com'è agente riducente;

2) Adupratu cum'è stabilizzatore di fibre artificiali, agente sbiancante di tessuti, sviluppatore fotograficu, disossidante di tintura è sbiancante, agente di riduzzione di sapori è tintura, eliminatore di lignina di carta, etc.

3) Adupratu cum'è un reattivu analiticu cumuni è materiale di resistenza fotosensibile;

4) Agente sbiancante riduttivu, chì hà un effettu sbiancante nantu à l'alimentariu è un forte effettu inhibitore nantu à l'ossidasi in l'alimentu vegetale.

5) L'industria di stampa è di tintura cum'è deoxidizer è bleach, utilizata in a cucina di diversi tessuti di cuttuni, pò impedisce l'ossidazione lucale di fibra di cuttuni è affettà a forza di a fibra, è migliurà a bianchezza di a sustanza di cucina. L'industria fotografica l'utiliza cum'è sviluppatore.

6) Adupratu da l'industria tessili cum'è stabilizzatore per fibre artificiali.

7) L'industria elettronica hè aduprata per fà resistori fotosensibili.

8) Industria di trattamentu di l'acqua per l'elettroplating, u trattamentu di l'acqua potabile;

9) Adupratu cum'è bleach, cunservatore, agenti allentanti è antioxidanti in l'industria alimentaria. Hè ancu usatu in a sintesi farmaceutica è cum'è un agente riducente in a produzzione di vegetali disidratati.

10) Adupratu per a pruduzzione di l'estere di sulfite di cellulosa, tiosulfatu di sodiu, sustanzi chimichi organici, tessuti sbiancati, etc., ancu usati com'è agenti riducenti, conservanti, agenti di dechlorazione, etc.;

11) U laboratoriu hè adupratu per preparà diossidu di sulfuru

Asia Africa Australasia

Europa Mediu Oriente

America di u Nordu America Centrale / Sudamerica

Specificazione generale di imballaggio: 25KG, 50KG; 500KG; 1000KG, 1250KG Jumbo Bag;

Dimensione di l'imballu: Dimensione di u saccu Jumbo: 95 * 95 * 125-110 * 110 * 130;

Dimensione di u saccu di 25 kg: 50 * 80-55 * 85

U saccu chjucu hè un saccu di doppia strata, è a capa esterna hà un film di rivestimentu, chì pò impedisce efficacemente l'assorbimentu di umidità. Jumbo Bag aghjunghjenu additivu di prutezzione UV, adattatu per u trasportu longu, è ancu in una varietà di clima.

Terminu di pagamentu: TT, LC o per negoziazione

Portu di Carica: Portu di Qingdao, Cina

Tempu di consegna: 10-30 ghjorni dopu a cunfirmazione di l'ordine

Small Oders Accepted Sample Disponibile

Distributori Offerte Reputazione

Prezzu Qualità Spedizione pronta

Garanzia di Approvazioni Internaziunali / Garanzia

Paese d'origine, CO/Formula A/Formula E/Formula F...

Avè più di 10 anni di sperienza prufessiunale in a produzzione di sulfitu di sodiu;

Puderia persunalizà l'imballu secondu a vostra esigenza; U fattore di sicurità di u saccu jumbo hè 5: 1;

Un picculu ordine di prova hè accettabile, un campione gratuitu hè dispunibule;

Fornite analisi di u mercatu ragiunate è suluzione di produttu;

Panoramica di u risicu

Periculi per a salute: per l'ochji, a pelle, irritazione di a mucosa.

Periculi ambientali: periculi per l'ambiente, ponu causà contaminazione à i corpi d'acqua.

Periculu d'esplosione: u pruduttu ùn hè micca combustibile è irritante.

Misure di primu aiutu

Cuntattu cù a pelle: sguassate i vestiti contaminati è sciacquate cù abbondante acqua corrente.

Cuntattu cù l'ochji: Lift eye eyes è risciacquate cù acqua corrente o salina. Andate à un duttore.

Inalazione: luntanu da a scena à l'aria fresca. Dà l'ossigenu si avete difficultà à respira. Andate à un duttore.

Intake: beie abbastanza acqua calda per induce u vomitu. Andate à un duttore.

Misure di cuntrollu di u focu

Caratteristichi periculosi: senza caratteristiche di combustione è splusioni spiciali. A decomposizione termale alta produce fumi di sulfuru tossicu.

Pruduttu di combustione dannosu: sulfuru.

U metudu d'extinzione di u focu: u persunale di u focu deve portà u corpu tutale di u focu - vestiti a prova, a lotta di u focu in u ventu. Quandu si spegne u focu, move u cuntinuu quantu pussibule da u situ di u focu à una zona aperta.

Risposta d'emergenza à a fuga

Trattamentu d'urgenza: isolate l'area contaminata di fuga è restringe l'accessu. Hè ricumandemu chì u persunale di emergenza portà maschere di polvere (copertura completa) è vestiti di gas. Evitate a polvera, spazzate cù cura, mette in sacchetti è trasferisce in un locu sicuru. Pò esse ancu lavatu cù assai acqua è diluitu in u sistema d'acqua residuale. riciclà o trasportu à u locu di eliminazione di i rifiuti per a eliminazione.

Eliminazione di l'operazione è almacenamentu

Precauzioni per l'operazione: operazione ermetica, rinfurzà a ventilazione. L'operatori deve esse addestrati in particulare è seguite strettamente e procedure operative. L'operatori sò cunsigliati di portà maschere di polveri di filtri auto-aspiranti, purtassi occhiali protettivi di sicurezza chimica, purtassi salopette anti-permeazione antitossica, è guanti di gomma. equipaggiu.I cuntenituri vioti ponu ritene sustanzi nocivi.

Precauzioni per l'almacenamiento: Mantene in un magazzinu frescu è ventilatu. Mantene luntanu da u focu è u calore. Deve esse separatu da l'acidu è l'altru almacenamentu, ùn mischjà micca u almacenamentu. Ùn dura micca longu. L'area di almacenamento deve esse furnita cù materiali adattati per mantene a fuga.

Cuntrolla di cuntattu / prutezzione persunale

U cuntrollu di l'ingegneria: u prucessu di produzzione hè chjusu, è a ventilazione hè rinfurzata.

Prutezzione di u sistema respiratoriu: quandu a cuncentrazione di polvera in l'aria supera u standard, duvete portà una maschera di polvera di filtru autosuzione.

Prutezzione di l'ochji: portà occhiali di sicurezza chimica.

Prutezzione di u corpu: purtate vestiti di travagliu anti-tossicu.

Prutezzione di e mani: purtate guanti di gomma.

Altra prutezzione: cambià a ropa di travagliu in tempu. Mantene una bona igiene.

Stabilità è reattività

Stabilità: Instabilità

Composti pruibiti: acidu forte, aluminiu, magnesiu.

Prudutti di descomposizione: diossidu di sulfuru è sulfate di sodiu

Biodegradabilità: non biodegradabilità

Altri effetti dannosi: a sustanza hè dannosa per l'ambiente, una attenzione particulari deve esse pagata à a contaminazione di l'acqua.

Trasportu

Precauzioni di u trasportu: L'imballu deve esse cumpletu è a carica deve esse sicura. Assicuratevi chì u cuntinuu ùn sguassate, colapsà, cascate o danni durante u trasportu. Hè strettamente pruibitu di mischjà cù acidi è sustanzi chimichi comestibili. U trasportu deve esse prutettu contra l'esposizione à u sole, a pioggia è a temperatura alta.